Federal Lead and Copper Rule Revisions

The Environmental Protection Agency (EPA) announced its first major revision to the Lead and Copper Rule (LCR) on December 16, 2021. The new LCR prioritizes protecting children from the dangers of lead exposure and introduces changes designed to expedite the removal of lead from drinking water in the most at-risk communities across the country.

| Service Line Inventories and Replacement | All water systems have until October 2024 to develop initial LSL inventories or demonstrate the absence of LSLs. LSL inventories must identify the materials used in both the public and private side of the service line, be routinely updated, and made publicly available. All water systems with known or possible LSLs will be required to immediately develop a LSL replacement program that includes a funding strategy and action plan that prioritizes the needs of communities facing the greatest risk of lead exposure. Note: on August 4, 2022, the EPA released its Guidance for Developing and Maintaining a Service Line Inventory (more details). |

| Public Communication | A water system with LSLs must notify households with service lines made of lead or unknown materials within 30 days of completing its initial LSL inventory. The notification must include information about the health risks associated with lead exposure, actions homeowners can take to reduce lead exposure, and how to identify and remove LSLs. Water systems serving more than 50,000 people must make their LSL inventories available via a website. |

| Sampling Requirements | Fifth-liter water sampling will now be required at sites serviced by LSLs. In locations with water samples that exceed the lead action level of 15 ug/L, water systems must enact a “find-and-fix” strategy that requires corrective action be taken within 30 days. |

| Corrosion Treatment and Water Quality Guidelines | Water systems are now subject to new corrosion control treatment (CCT) requirements and water quality parameters based on their lead sampling results and system size. For example, water systems with 90th percentile lead levels greater than 15 ug/L must install CCT immediately or re-optimize their existing CCT efforts. |

| Schools and Child Care Facilities | Water systems must test drinking water for lead at 20% of elementary schools and licensed child care facilities in their service areas each year and conduct water sampling at secondary schools upon request. |

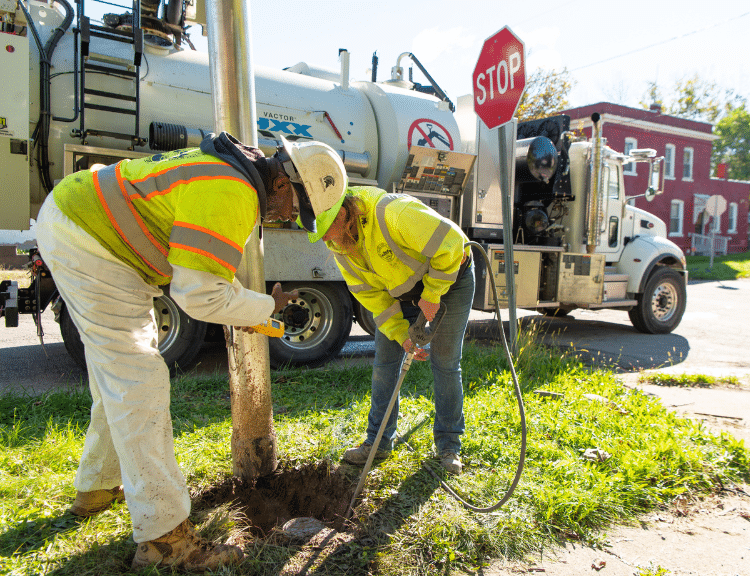

Get Help with your LSL Inventory and Replacement Plan

BlueConduit has been helping water systems identify, prioritize, and replace LSLs since 2016. Let us help you plan your LSLR program, inventory your LSLs, and optimize your LSLR efforts.